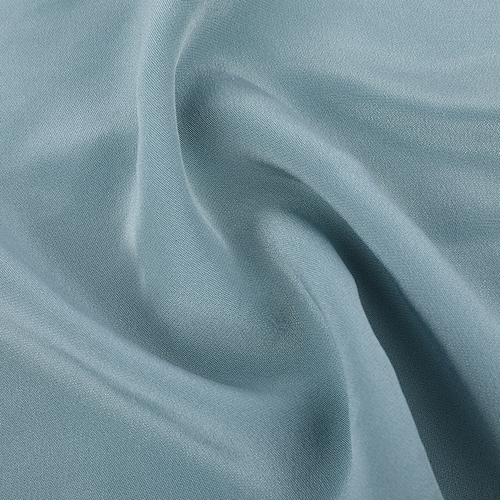

Physicochemical properties of tussah cocoon silk

Tussah cocoon silk is composed of two flat fibers with an obtuse triangle in cross section. The content of silk fibroin is as high as about 85%. After repeated refining in soap lye, the weight loss is only 10-11%.

Tussah cocoon silk contains more pigments, often pale yellow and light brown, and some pigments are firmly combined with silk fibroin, which is not easy to remove during bleaching.

Tussah cocoon silk is relatively thick, and the commonly used strands are above 35D, so the strength of the fabric is high, and the wet state is higher than the dry state, which is durable, washable and durable, but it is easy to stretch after moisture absorption, so the tussah silk is moist When wet and re-dried, there is only a 2.5% shrinkage. At the same time, the tussah fiber will also curl, and its degree varies with the temperature. Contraction" expresses two different states. Because crimping gives the fiber a corrugated appearance that does not disappear after refining.

Tussah cocoon silk has strong heat resistance. When pressure-treated in high temperature water, only part of sericin is decomposed, and silk fibroin is not damaged by heat resistance. Bake at 140 ℃ for 30 minutes, the strength will gradually weaken, and the strength will decrease sharply when it is dried above 200 ℃.

Tussah cocoon silk has strong acid and alkali resistance, and is relatively stable to oxidants such as hydrogen peroxide, but it is not stable enough under pressurized steam for a long time. It is precisely because tussah silk cannot react sensitively to chemical solution treatment, so it brings many difficulties to refining, bleaching and dyeing processes.

The oxidative effect of light on tussah cocoon silk is more severe, making the fiber brittle and reducing the strength and elongation.

English

English

中文简体

中文简体